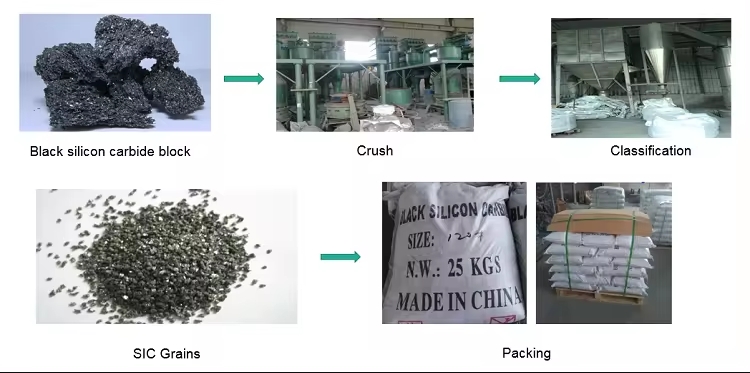

Black Silicon carbide (SiC) is using quartz sand and petroleum coke or coal tar, wood chips as raw material through high temperature electric resistance furnace smelting.There is also a rare mineral silicon carbide in nature, the mo SangShi.Silicon carbide is also called the moissanite.In contemporary ,C, N, B the oxide refractory raw materials are used in the high technology, such as silicon carbide as the most widely used, one of the most economic material ,can be called corundum sand or refractory.At present, the industrial production of silicon carbide can be divided into two kinds: black silicon carbide and green silicon carbide, are the six-party crystal, specific gravity of 3.20 ~ 3.25, the microhardness of 2840 ~ 3320 kg/mm2.

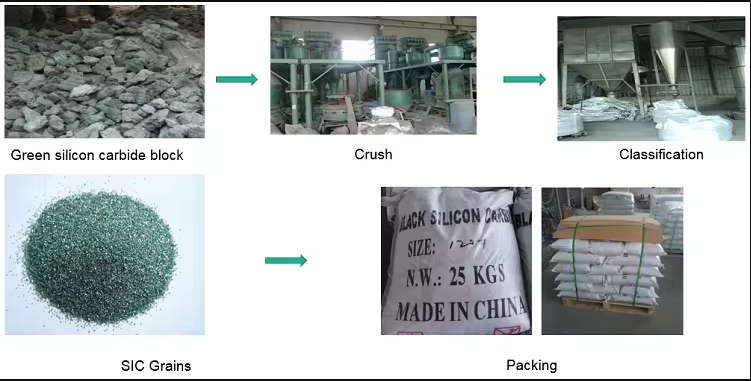

Green silicon carbide is made of petroleum coke and high quality silica as main raw materials, adding salt as additive, and smelting at high temperature in resistance furnace. Green crystal, brittle and sharp, and has a certain thermal conductivity and electrical conductivity.

Its crystallization have higher purity and hardness. Green silicon carbide is suitable for processing hard alloy, metallic and non-metallic material with hard and brittle feature such as copper, brass, aluminium, magnesslum, jewel, optical glass, ceramics, etc. Super Micropowder of it is also a kind of ceramics material.