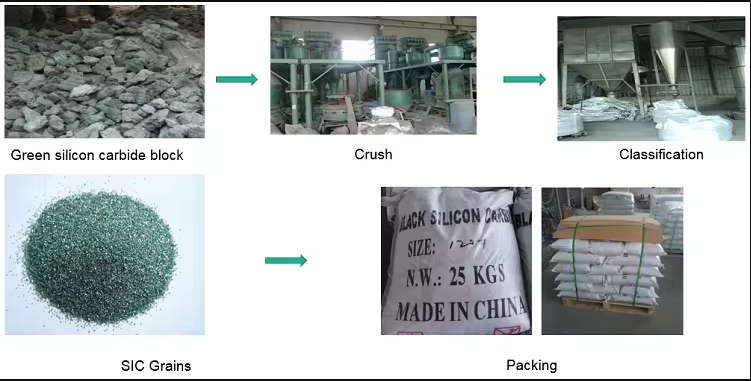

Green silicon carbide is made of petroleum coke and high quality silica as main raw materials, adding salt as additive, and smelting at high temperature in resistance furnace. Green crystal, brittle and sharp, and has a certain thermal conductivity and electrical conductivity.

Its crystallization have higher purity and hardness. Green silicon carbide is suitable for processing hard alloy, metallic and non-metallic material with hard and brittle feature such as copper, brass, aluminium, magnesslum, jewel, optical glass, ceramics, etc. Super Micropowder of it is also a kind of ceramics material.

1. Low density

2. High strength

3. High temperature strength (reactive bonding)

4. Oxidation resistance (reaction bonding)

5. Excellent thermal shock resistance

6. High hardness and good wear resistance

7. Excellent chemical resistance.

size | |

Grit | 4#,5#,6#,8#,10#,12#,14#,16#,20#,22#,24#,30#,36#,40#,46#,54#,60#,70#,80#,90#,100#,120#,150#,180#,220# |

Micro-powder | 240#,280#,320#,360#,400#,500#,600#,700#,800#,900#,1000#,1200#,1500#,2000#,2500#, 3000#,4000#,6000#,8000#,10000# |

Typical physical Analysis | |

Test items | indicators |

Mohs hardness | 9.5 |

Knoop hardness | 2670-2815kg/mm2 |

Real density | 3.2-3.25g/cm3 |

Melting point | 26000C |

Bulk density | 1.2-1.6 g/cm3 |

Typical Chemical Analysis | |

SiC | 99.05% |

SiO2 | 0.2% |

Si | 0.03% |

Fe | 0.04% |

C | 0.1% |

Green Silicon Carbide For abrasive: Lapping, Polishing , Coatings, Grinding , Pressure blasting.

Green Silicon Carbide For refractory: Refractory media for casting or metallurgical linings ,Technical Ceramics.

Green Silicon Carbide For new-type application: Heat exchangers ,Semiconductor process equipment , Liquid filtration.