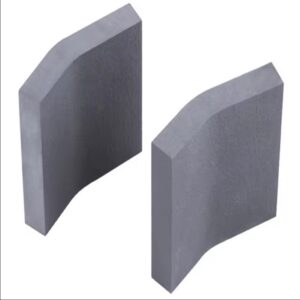

Boron carbide is hard black with glossy crystals. Hardness is lower than industrial diamond, but higher than silicon carbide. It is less vulnerable than most pottery. It has a large thermal neutron capture cross section. Strong resistance to chemistry. The erosion of hydrogen fluoride and nitric acid. Soluble in molten base, insoluble in water and acid.

relative density | Melting Point | Boiling point | Crystal Structure | Mohs Hardness | Micro Hardness |

2.5g/cm3 | 2350°C

| 3500°C | Rhombohedral

| 9.3

| 4950kgf/mm2 |

type | Basic particle sizes | Total carbon content | Total boron content | B+C% |

CT% | BT% | |||

F40 | 425 | 17-21.5 | 76-80 | 95-98 |

F46 | 355 | |||

F54 | 300 | |||

F60 | 250 | |||

F70 | 212 | |||

F80 | 180 | |||

F90 | 150 | |||

F100 | 125 | |||

F120 | 106 | |||

F150 | 75 | |||

F180 | 75-63 | |||

F220 | 63-53 | |||

F230 | D50=53 | 75-79 | 95-97 | |

F240 | D50=44.5 | |||

F280 | D50=36.5 | |||

F320 | D50=39.5 | |||

F360 | D50=22.8 | |||

F400 | D50=17.3 | |||

F500 | D50=12.8 | |||

F600 | D50=9.3. | 74-79 | 93-97 | |

F800 | D50=6.5 | |||

F1000 | D50=4.5 | |||

F1200 | D50=4.5 | |||

F1500 | <5 | |||

325#-0 | <150 | 17-21 | 75-80 | 93-97 |

Used for tank armor and body armor

Used for product grinding and drill

Be used to produce alloy powder so as to improve the life of the mechanical component;