Foundry chromite sand is a natural process products of chromite through the broken screen classification, chrome ore, its main chemical composition of cr2o3, this kind of sand heated volume stability, high thermal conductivity, when in contact information with the molten metal, not only has good resistance to basic slag, not with ferric oxide and other chemical reactions, and itself has the characteristics of the solid phase sintering, can be a very good prevent the infiltration of molten metal, avoid to touch sand defects, suitable for all kinds of stainless steel, alloy steel and carbon steel gradually shape the original sand core and coating.

Index | Physics | Index | |

Cr2O3 | ≥46.0% | Bulk Density | 2.5-3g/cm³ |

SiO2 | ≤1.0% | PH Value | 7-9 |

Fe2O3 | ≤26.5% | Cr/Fe | 1.55:1 |

CaO | ≤0.30% | Filling Density | 2.6 g/cm³ |

MgO | ≤10% | Percent Moisture | ≤0.1 |

AI2O3 | ≤15.5% | The sintered | 1600°C |

P | ≤0.003% | Sintering Temperature | 2180°C |

C | ≤0.003% | Melting Point | >1800°C |

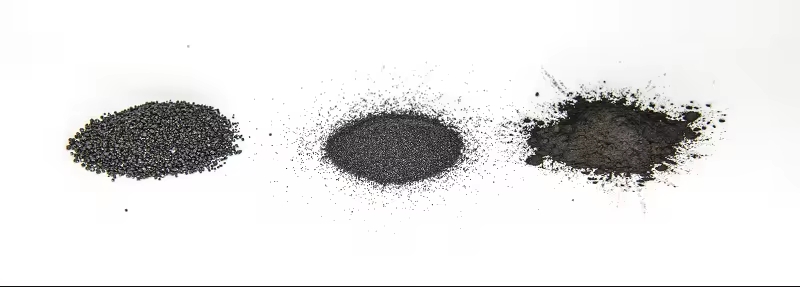

Regular size | |||

AFS 25-35 AFS25-30 AFS30-35 AFS35-40 AFS40-45 AFS45-50 AFS50-55 AFS55-60 AFS60-65 | |||

Chromite Sand in the foundry industry

Its properties enable the material to be used in high duty grey iron and steel foundries as core and mould making sand. Its high thermal conductivity gives it good chilling properties, low thermal expansion gives rise to good dimensional stability. Its basicity being close to neutral allows the use of a wide range of resin bonding systems and inorganic binders, it has a high refractoriness and a broad sieve distribution.

Chromite Sand in the steel industry

In steel production, Chromite Sand is used as well filler for protection of the sliding gate in large steel holding ladles.

Chromite Sand in the glass industry

When ground to a fine flour, Chromite Sand is used for the production of green glass beverage containers.

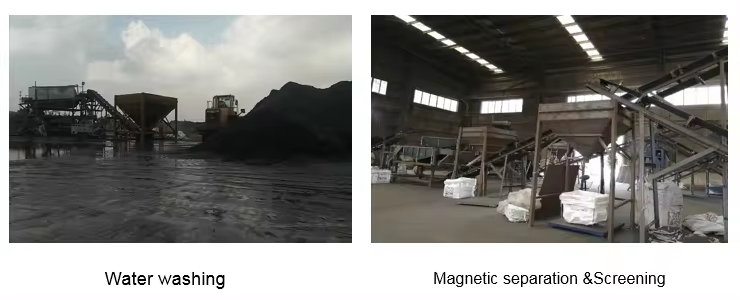

Step1: chrome ore raw material is processed by water washing.

Step2, drying raw materials to remove water;

Step3, drying raw materials into the vibrating screen, screening out the size of the customer needs;

Step4, the size of the sieve for magnetic separation, the purpose of iron and silicon removal. After magnetic separation, the chromium content reached more than 46% and the silicon content was less than 1%.

Step5: package the finished product.