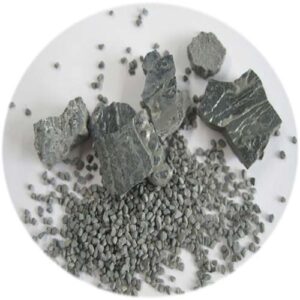

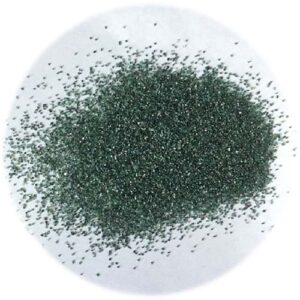

Silicon carbide (SiC) is using quartz sand and petroleum coke or coal tar, wood chips as raw material through high temperature electric resistance furnace smelting.There is also a rare mineral silicon carbide in nature, the mo SangShi.Silicon carbide is also called the moissanite.In contemporary ,C, N, B the oxide refractory raw materials are used in the high technology, such as silicon carbide as the most widely used, one of the most economic material ,can be called corundum sand or refractory.At present, the industrial production of silicon carbide can be divided into two kinds: black silicon carbide and green silicon carbide, are the six-party crystal, specific gravity of 3.20 ~ 3.25, the microhardness of 2840 ~ 3320 kg/mm2.

Used for abrasive, blasting, grinding. | |||

Properties type | 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#. | ||

Guarantee Value | Typical Value | ||

Chemical composition | SIC | 98.0 min | 98.5 |

F.C | 0.2 max | 0.1 | |

Fe2O3 | 0.2 max | 0.15 | |

H2O | 1.0max | 0.30 | |

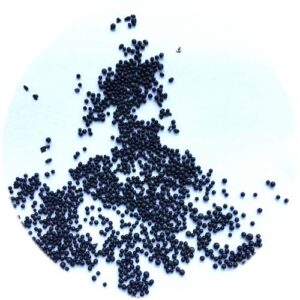

Product Name | Black silicon carbide |

Model Number | 8–220#,240#–8000#,F230-F2000. |

Material | SiC |

Feature | High Purity |

Color | black |

Moh’s hardness | 9.15 |

Real density | 3.2-3.45g/cm3 |

Melting point | 2250 ℃ |

Maximum service temperature | 1900℃ |

For abrasive: Lapping, Polishing , Coatings, Grinding , Pressure blasting.

For refractory: Refractory media for casting or metallurgical linings ,Technical Ceramics.

For new-type application: Heat exchangers ,Semiconductor process equipment , Liquid filtration.

1. Low density

2. High strength

3. High temperature strength (reactive bonding)

4. Oxidation resistance (reaction bonding)

5. Excellent thermal shock resistance

6. High hardness and good wear resistance

7. Excellent chemical resistance.