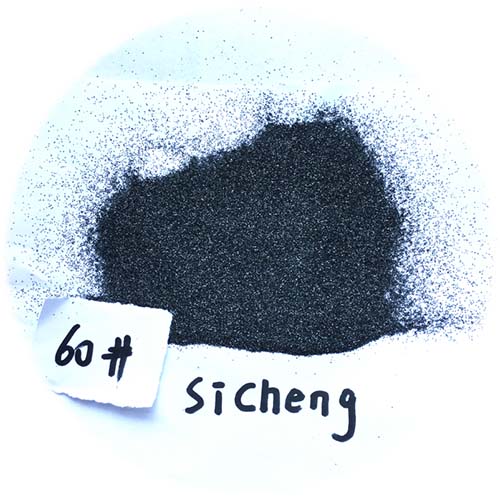

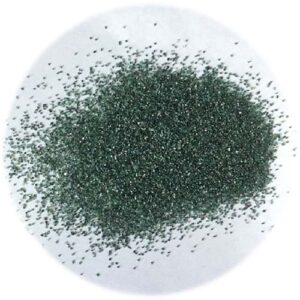

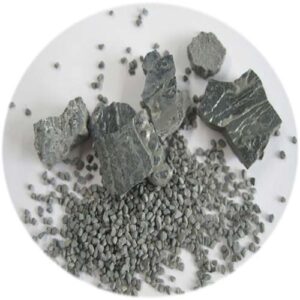

SiC Black silicon carbide is made of quartz sand, petroleum coke and high-quality silica as the main raw materials, and is smelted by electric furnace at high temperature. Black silicon carbide powder / Sic can used for refractory purpose or in electronic industry.Silicon Carbide powder / Sic also has the resistivity necessary to perform as a semiconductor material. Because of these properties, Silicon Carbide is used in a wide range of applications and industries.

Used for abrasives, lapping, polishing | ||||

Properties Type | FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | ||

JIS | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# | |||

Guarantee Value | Typical Value | |||

Chemical composition | SIC | 97.0 min | 97.5 | |

F.C | 0.3max | 0.2 | ||

Fe2O3 | 0.2 max | 0.15 | ||

H2O | 1.0max | 0.3 | ||

Black Silicon carbide : F12-F14,use for sandblasting,rust removal,snagging,heavy duty grinding of steel ingot,leather,salt,floor boards.

Black Silicon carbide : F14-F30,use for casting play burr,cutting billet and steel tube,flat kibbling,steel ingot grinding,marble grinding,or as refractory material.

Black Silicon carbide : F30-F60,use for surface abrasion,outside&surface grinding,centerless grinding,tool grinding of quenching or no-quenching steel profiles,copper or other hard metal.

Black Silicon carbide : F60-F100,use for precision grinding, cutter sharpening,gear grinding,etc.

Black Silicon carbide : F100-F240,use for cutter sharpening,rough grinding,precision grinding,thread grinding.

Black Silicon carbide : F280-F600,use for precision grinding&thread grinding of instrument and matter an gear products.

Black Silicon carbide : F600-F2000,super-precision polishing,mirror polishing,surface lapping,etc.