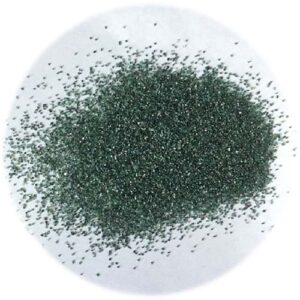

Brown Fused Alumina for Sandblasting

Brown fused aluminum oxide, otherwise known as Brown Fused Alumina or BFA, is produced through an electric arc furnace process. Brown fused aluminum oxide is both a hard (Mohs hardness 9) and tough material with high strength, making it an excellent abrasive grain raw material for applications such as blast media, sandpaper, grinding wheels and abrasive discs, rolls, belts and pads. Its thermal properties make it an excellent raw material for refractory applications, as well.

Because Brown Fused Aluminum Oxide has a high bulk density and high hardness making it the perfect media for removing rust, mill scale, and surface contamination. The consistent particle size allows for a uniform surface finish and coverage.

Additionally, BFA has a low friability which allows it to be recirculated on average, up to seven times. These characteristics reduce abrasive consumption, clean up, and disposal costs, increasing profitability.

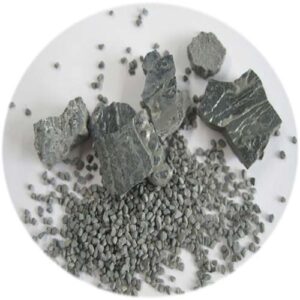

1. Brown corundum is characterized by high purity, dense texture, large stacking density, strong self-sharpness, good toughness and extremely low magnetic content;

2. The grinding tool made of it has the advantages of sharp grinding, low heating rate, high grinding ratio and less adhesion in use;

3. The sintered abrasive tool has the characteristics of deep blue color, no network crack and no rust spot after firing.

Indicators | |

Mohs hardness | 9.0 |

Bulk density | 1.53-1.99g/cm3 |

Real density | 3.6-3.9g/cm3 |

Melting point | 22500C |

The highest operating temperature | 19000C |

Used for abrasive, blasting, grinding. | |||

Properties type | 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#. | ||

Guarantee Value | Typical Value | ||

Chemical composition | AI2O3 | 95.0 min | 95.65 |

SiO2 | 1.5 max | 1.04 | |

Fe2O3 | 0.5 max | 0.14 | |

TiO2 | 3.0max | 2.20 | |

1. Sandblasting and grinding of metal and non-metal products.

2. Architectural ceramics, special ceramics and technical ceramics.

3. Rough grinding and high-pressure cutting, wear-resistant products, as additives.

4. Resin abrasives, coated abrasives in sandpaper, gauze and other manufacturers of raw materials.

Henan sicheng Abrasives Co.,ltd.was established in 2009. It covers the area of 10 years. With updated new equipment, our factory can produce White Fused Alumina 15,000 tons per year, Brown Fused Alumina 15,000 tons per year and Slilicon carbide 2,000 tons per year. It is one of the high grade abrasive grains production base in China.

We have our own individual laboratory, the testing method for particle size is laser measuring method. From raw material choosing and purchasing, production processes, to market & sales, we all have very high standards. Which makes our products very popular among Japan, Korea, Southeast Asia, Middle East and European countries.