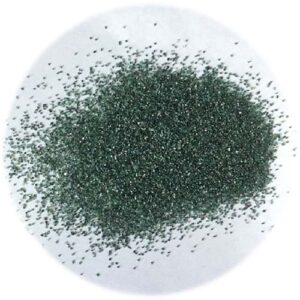

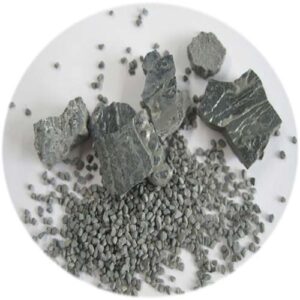

Glass beads are made of broken glass, flat glass and other raw materials by high temperature melting bead processing. Low thermal conductivity, high strength, good chemical stability, and the texture of glass beads themselves, glass beads instead of plastic raw materials are widely used in filling, such as gravity blanket filling, compression filling, medical filling, weighted blanket filling, toy filling and so on.

Advantage of SICHENG Glass beads:

1. The chemical composition is inert silicon dioxide and there is no worry about the interference of chemical activity;

2, round elastic particles, impact resistance, can be recycled many times, less loss;

3, the spray wear is small, extend the service life of the nozzle;

4, the surface of the ball, will not damage the processing surface and precision size;

5. After treatment, the work-piece surface is smooth, with a special aesthetic feeling, improving the product value;

6. Suitable for dry and wet sand blasting;

7. The fine glass beads used for the metal micro-cracks can be easily displayed after the wet sandblasting;

8, for the processed work-piece with matte effect, highlighting the metal color, not rust and other advantages, no need to carry out pickling derusting treatment.

Glass beads 0.6mm 0.8mm 1mm 1.2mm 2mm weighted blanket stuffing filling media

SiO2 | Na2O | CaO | MgO | Al2O3 | K2O | Fe2O3 | Other |

70-74% | 12-15% | 8-10% | 1-3.8% | 0.2-1.8% | 0-0.15% | 0-0.15% | 0-2% |

Physical properties | |||

Reflective: | 1.7 | Color | Colorless Transparent |

Mohs Hardness | 7 | HRC hardness | 46 |

Real Density | 2.5g/cm3 | Bulk Density | 1.5g/cm3 |

1,Road making, airport road marking;

2,Fillers for various insulation and sound insulation products;

3,Enhance stress corrosion resistance. For example, aircraft engine turbo, vane, shaft, undercarriage, diversified springs and gears, etc

4,provide brightness for medical mechanical instruments and automobile parts

5,Be used for reflective safety clothing to improve safety.

Production process: