Fused zirconia alumina is a high grade abrasives materials and fused corundum zirconium of bonded abrasive materials, fused zirconia alumina can application high grade refractory materials. It is high strength, high toughness, high temperature characteristics of Zirconia corundum, Fused zirconia alumina can manufacturer abrasive and High-performance heavy-duty sand wheels, also can application for Iron and steel industry, continuous casting and rolling, nozzle, flow channel, glass furnace refractories, etc. fused corundum zirconium can use of steel, cast iron, heat-resistant steel, titanium, nickel alloy, aluminum alloy, titanium alloys and other tungsten grinding. There are several names of fused corundum zirconium, such as Zirconium Oxide, Zirconia Aluminum Oxide (ZA), Fused Alumina ZA 25, zirconium corundum etc.

Chemical properties | |||||

Product series | AlO3% | ZrO2% | TiO2% | Fe2O3% | SiO2% |

ZA25 | 68%-72% | 24%-30% | 1.5%Max | 0.5%Max | 1.0%Max |

ZA40 | 55%-57% | 35%-44% | 1.5%Max | 0.5%Max | 1.0%Max |

Physical properties | |

Crystal form | Monoclinic, tetragonal system |

Crystal size | ≤30μm |

True density | 4.20g/cm3 |

Bulk density | 2.18g/cm3 |

Moh’s hardness | 9.0 |

Knoop hardness | 1450-2000kg/cm2 |

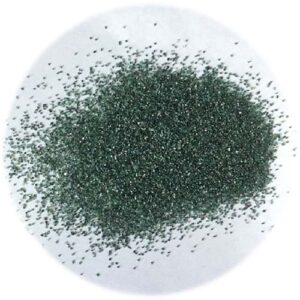

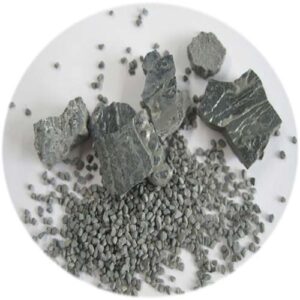

The color | Gray |

Melting point | 1900℃ |

The highest use temperature | 1600℃ |

Reaction with acid and alkali | No |

Reaction with carbon | Forming carbide since 1650℃ |

Specific heart capacity(cal/g.℃) | 0.2205(50-500℃) |

Heat Conductivity | 0.2718cal/cm2.sec.℃ |

Linear expansivity (X10-6) | 682(100-700℃) |

Available size |

FEPA | F4 F5 F6 F7 F8 F10 F12 F14 F16 F20 F22 F24 F30 F36 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 |

JIS | JIS#4 JIS#5 JIS#6 JIS#7 JIS#8 JIS#10 JIS#12 JIS#14 JIS#16 JIS#20 JIS#24 JIS#30 JIS#36 JIS#46 JIS#54 JIS#60 JIS#70 JIS#80 JIS#90 JIS#100 JIS#120 JIS#150 JIS#180 JIS#220 | |

0-0.5MM 0.5-1MM 1-1.5MM 0-1MM 1-2MM 2-3MM 1-3MM 3-5MM | ||

1) High hardness.

2) High Tension.

3) Good Self-Sharpening.

4) Good Thermal Stability.

5) High Temperature Resistance.

6) Anti-corrosion.

7) Stable Chemical Properties.

1.It can make high performance heavy duty grinding wheel, in grinding steel, cast iron, heat-resistant steel, titanium alloy, aluminum alloy, tungsten alloy and other aspects have achieved good results. Widely used in continuous casting and rolling, runner, glass and other steel industry refractory production.

2.Zirconium corundum is a high strength, high toughness, high self – sharpening high – quality wear – resistant refractory. The most common applications are high pressure grinding wheels and pressure blasting on very hard surfaces.