Pink fused alumina is electrically fused in high temperature, being added with the right quantity of oxidized chromium. It is pink. Its hardness is close to WA, but toughness is higher than WA.

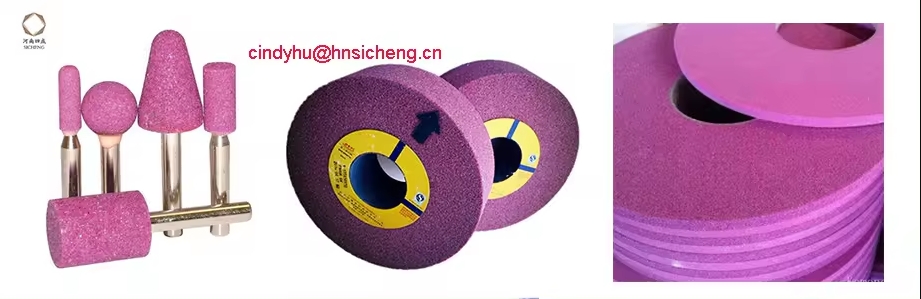

The abrasive tools made of it feature excellent durability and high processing cleanness, which are suitable for the precision grinding of the measuring tolls, lathe main shafts, instruments and apparatus parts, threading work pieces and samplers, etc

Physical Property | Basic Minerals | α— AI2O3 | |

Crystal size | μm | 600~2000 | |

True density | g/cm3 | ≥3.90 | |

Bulk density | g/cm3 | 1.40~1.91 | |

Knoop hardness | g/mm2 | 2200~2300 |

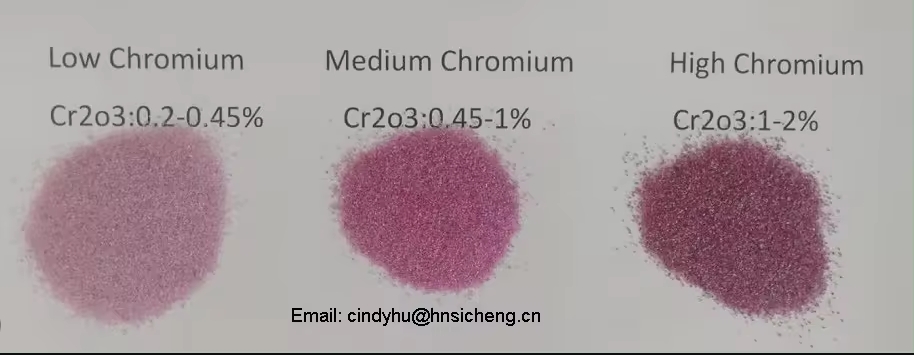

Specification | Low chromium | Medium chromium | High chromium | ||||||

Al2O3 (%) | Cr2O3 (%) | Na2O (%) | Al2O3 (%) | Cr2O3 (%) | Na2O (%) | Al2O3 (%) | Cr2O3 (%) | Na2O (%) | |

F12-F80 | ≥98.50 | 0.20-0.45 | ≤0.50 | ≥98.20 | 0.45-1.00 | ≤0.55 | ≥97.40 | 1.00-2.00 | ≤0.55 |

F90-F150 | ≥98.50 | 0.20-0.45 | ≤0.50 | ≥98.20 | 0.45-1.00 | ≤0.60 | ≥97.00 | 1.00-2.00 | ≤0.60 |

F180-F220 | ≥98.50 | 0.20-0.45 | ≤0.50 | ≥97.80 | 0.45-1.00 | ≤0.70 | ≥96.50 | 1.00-2.00 | ≤0.70 |

1, Pink fused alumina for surface processing: metal oxide layer, carbide black skin, metal or non-metal surface rust removal, such as gravity die-casting mold, rubber mold oxide or free agent removal, ceramic surface black spot, uranium removal, painted rebirth.

2, Pink fused alumina beautification processing: all kinds of gold, gold jewelry, precious metal products of the extinction or fog surface processing, crystal, glass, ripple, acrylic and other non-metallic fog surface processing and can make the surface of the processing into metallic luster.

3. Pink fused alumina for Etching and processing: etching artists of jade, crystal, agate, semi-precious stone, seal, elegant stone, antique, marble tombstone, ceramics, wood, bamboo, etc.

4. Pink fused alumina for Pretreatment: TEFLON, PU, rubber, plastic coating, rubber ROLLER, electroplating, metal spray welding, titanium plating and other pretreatment, so as to increase the surface adhesion.

5.Pink fused alumina for Burr processing: burr removal of bakelite, plastic, zinc, aluminum die-casting products, electronic parts, magnetic cores, etc.

6, Pink fused alumina for stress elimination processing: aerospace, national defense, precision industry parts, rust removal, painting, polishing, such as stress elimination processing.